-

Stainless Steel Sheet Plate

-

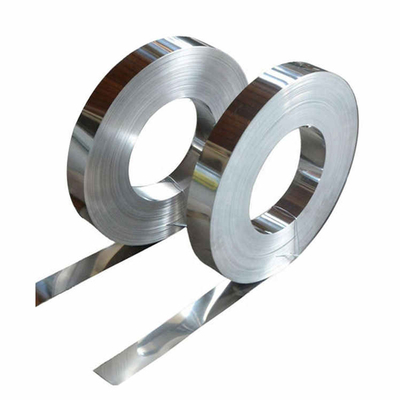

Stainless Steel Coil Strip

-

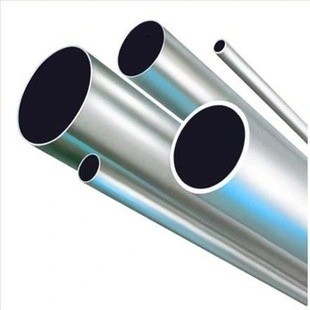

Stainless Steel Tube Pipe

-

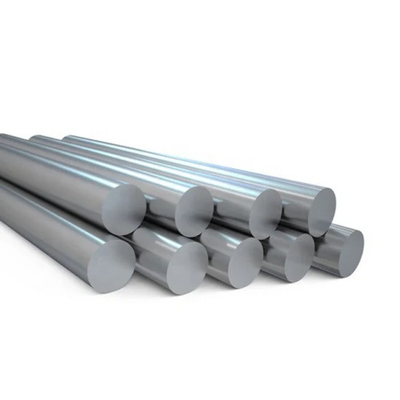

Stainless Steel Bar Rod

-

Galvanized Steel Sheet

-

Galvanized Steel Pipe

-

Carbon Steel Coil

-

Carbon Steel Pipe

-

Carbon Steel Bar

-

Gi Corrugated Sheet

-

Wear Resistant Steel Plates

-

Carbon Steel Sheet

-

Galvanized Steel Coil

-

Aluminium Sheet Plate

-

Copper Sheet Plate

-

Nickel Alloy Steel

-

316 SS Plate

-

304 Stainless Steel Tubing

Advanced Nickel Iron Chromium Alloy Steel Pipe Incoloy 800

| Place of Origin | China |

|---|---|

| Brand Name | Inconel |

| Certification | ISO, AISI, ASTM, GB, EN, DIN, JIS |

| Model Number | Incoloy 800 Advanced Nickel Alloy nickel-iron-chromium alloy |

| Minimum Order Quantity | 1 Ton |

| Price | Contact Us |

| Packaging Details | Waterproof Paper, Steel Strip Packed and other Standard Export Seaworthy Package, or customized |

| Delivery Time | Within 7-10 Working Days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 5000 Ton/Tons per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: [email protected]

If you have any concern, we provide 24-hour online help.

x| Material | Incoloy 800 Advanced Nickel Alloy Nickel-iron-chromium Alloy | Is Alloy Or Not | Is Alloy |

|---|---|---|---|

| Sample | Available | Seaport | Shanghai Port, Ningbo Port |

| Others | OEM/ODM/Oversea Service | Type | Nickel Bar,Nickel Pipe,Nickel Plate |

| Grade | Advanced Nickel Alloy Nickel-iron-chromium Alloy | Product Name | Incoloy 800 |

| High Light | Nickel Iron Chromium Alloy Steel Pipe,Incoloy 800 Nickel Alloy Steel Pipe,Advanced Nickel Chromium Alloy Steel Pipe |

||

Incoloy 800 Advanced Nickel Alloy nickel-iron-chromium alloy

Alloy 800 is a high-performance ultra-alloy made of iron, chromium, and nickel, which exhibits excellent strength and resistance to oxidation and carburization in high-temperature environments. It also has outstanding resistance to stress-corrosion cracking and good creep and rupture strength.

Alloy 800 finds numerous applications in various industries, including heat treating tools, radiant tubes, thermowells, retorts, muffles, lead pots, heat exchangers, tubing, and high-temperature applications.

Incoloy® 800H is a member of the 800 series of alloys, which is a nickel-iron-chromium alloy. Incoloy 800H has similar characteristics to other 800 alloys, including excellent resistance to oxidation, sulfidation, and carburization, and resistance to prolonged exposure to elevated temperatures. The addition of carbon and annealing treatment allows for greater creep and rupture properties above 1100° F (600° C). Incoloy 800H is also readily machinable by standard methods and can be welded with high-temperature materials.

Incoloy 800H has a slightly different chemical composition compared to other 800 alloys, with Fe content of 39.5% min, Ni content of 30-35%, and Cr content of 19-23%. It also contains Al+Ti at 0.23-1.20% and C at 0.05-0.10%.

Incoloy 800H and Nickel Alloy 800H are used by many industries, particularly those dealing with temperatures above 1100° F (600° C). These industries include manufacturing furnace parts and equipment, petrochemical and chemical processing, equipment for heat-treating, pressure veins, and heat exchangers, and hydrocarbon processing.

Al

0.15 - 0.60

Al + Ti

0.30 - 1.20

C

.10 max

Cr

19.0 - 23.0

Fe

39.5 max

Ni

30.0 - 35.0

Ti

0.15 - 0.60

Rod, Bar, Wire, Forgings, and Forging Stock

ASTM B 408 & ASME SB 408

ASTM B 564 & ASME SB 564

ASME Code Case 1325

ASME Code Case 1949

ISO 9723

ISO 9724

ISO 9725

BS 3076NA15

BS 3075NA15

SEW 470

VdTÜV 412 & 434

DIN 17460

EN 10095

Plate, Sheet, and Strip

ASTM A 240/A 480

ASME SA 240/SA 480

ASTM B 409/B 906

ASME SB 409/SB 906

ASME Code Case 1325

ASME Code Case 2339

BS 3072NA15

BS 3073NA15

SEW 470

VdTÜV 412 & 434

DIN 17460

EN 10028-7 & EN 10095

Pipe & Tube

ASTM B 163

ASME SB 163

ASTM B 407/B 829

ASME SB 407/SB 829

ASTM B 514/B 775

ASME SB 514/SB 775

ASTM B 515/B 751

ASME SB 515/SB 751

ASME Code Case 1325 and 1983

BS 3074NA15

SEW 470

VdTÜV 412 & 434

ISO 6207

DIN 17459

Fittings

ASTM B 366

ASME SB 366