-

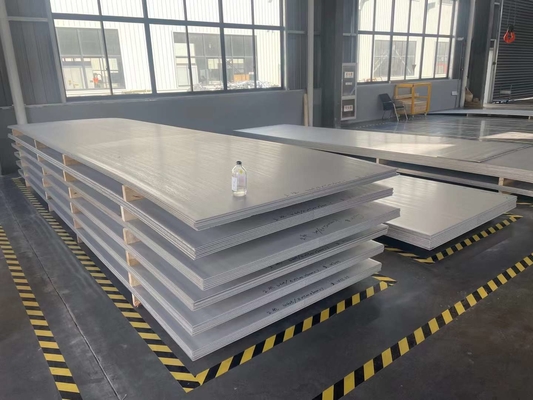

Stainless Steel Sheet Plate

-

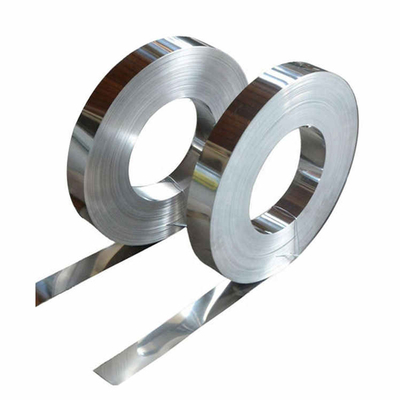

Stainless Steel Coil Strip

-

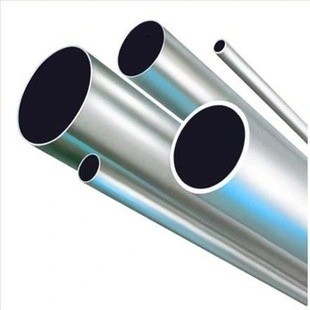

Stainless Steel Tube Pipe

-

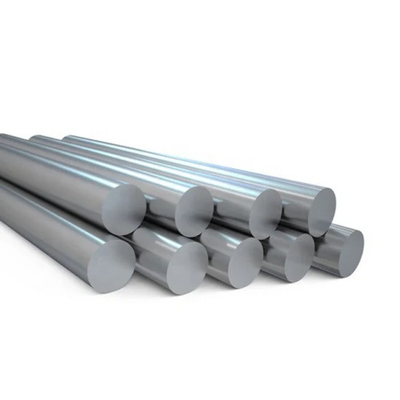

Stainless Steel Bar Rod

-

Galvanized Steel Sheet

-

Galvanized Steel Pipe

-

Carbon Steel Coil

-

Carbon Steel Pipe

-

Carbon Steel Bar

-

Gi Corrugated Sheet

-

Wear Resistant Steel Plates

-

Carbon Steel Sheet

-

Galvanized Steel Coil

-

Aluminium Sheet Plate

-

Copper Sheet Plate

-

Nickel Alloy Steel

-

316 SS Plate

-

304 Stainless Steel Tubing

Inconel X750 Nickel Chromium Alloy Steel All Standard Mill Forms High Strength

| Place of Origin | China |

|---|---|

| Brand Name | Inconel |

| Certification | ISO, AISI, ASTM, GB, EN, DIN, JIS |

| Model Number | Inconel X750 nickel-chromium alloy all standard mill forms |

| Minimum Order Quantity | 1 Ton |

| Price | Contact Us |

| Packaging Details | Waterproof Paper, Steel Strip Packed and other Standard Export Seaworthy Package, or customized |

| Delivery Time | Within 7-10 Working Days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 5000 Ton/Tons per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: [email protected]

If you have any concern, we provide 24-hour online help.

x| Material | Inconel X750 Nickel-chromium Alloy All Standard Mill Forms | Is Alloy Or Not | Is Alloy |

|---|---|---|---|

| Sample | Available | Seaport | Shanghai Port, Ningbo Port |

| Others | OEM/ODM/Oversea Service | Type | Nickel Bar,Nickel Pipe,Nickel Plate |

| Grade | Nickel-chromium Alloy All Standard Mill Forms | Product Name | Inconel X750 |

| High Light | Inconel X750 Nickel Chromium Alloy Steel,OEM Nickel Chromium Alloy Steel,high strength Nickel Chromium Alloy Steel |

||

Inconel X750 nickel-chromium alloy all standard mill forms

Inconel X-750® is a nickel-chromium alloy that offers high strength and resistance to corrosion and oxidation at temperatures up to 1300ºC. It is available in various mill forms, making it useful for a wide range of applications. Inconel X-750® is commonly used in rocket engine thrust chambers, gas turbine parts, and airframe components.

If you would like more information about our Inconel X750® products, please contact us or request a quote.

INCONEL® alloy X-750 (UNS N07750/W. Nr. 2.4669) is a precipitation-hardenable nickel-chrome alloy with excellent corrosion and oxidation resistance and high strength at temperatures up to 1300°F. Although its precipitation hardening effect decreases above 1300°F, the alloy retains practical strength up to 1800°F. It also exhibits good properties at cryogenic temperatures. The economic benefits and availability of INCONEL® alloy X-750 in all standard mill forms have made it a popular choice for applications in various industries. This alloy is commonly used for rotor blades, wheels, bolts, structural members in gas turbines, as well as rocket engine thrust chambers and hot environment ducting systems in airframes. Other applications include forming tools, heat-treating fixtures, extrusion dies, and test machine grips. INCONEL® alloy X-750 is suitable for spring suspensions and fasteners at temperatures ranging from sub-zero to 1200°F.

Inconel X750® Available Formats

Magellan Metals offers nickel alloy Inconel X-750® in a variety of forms, including:

- Bar

- Wire

- Sheet

- Plate

- Forgings

- Pipe fittings

- Flanges

- Seamless & Welded pipe

- Seamless Tube & Welded tube

- Weld Rod

Inconel X-750® Applications

Nickel alloy Inconel X-750® has many different industrial applications, some of which include:

- Nuclear reactors

- Gas turbines

- Rocket engines

- Pressure vessels

- Aircraft structures

Contact Magellan Metals Today

Use the above button to Contact us for more information on Inconel X-750®, call Magellan Metals at (203) 838-5700, or request a quote today.

| Chemical Analysis | |

| C | .08 max |

| MN | 1.00 max |

| S | .01 max |

| Si | .50 max |

| Cr | 14.0 -17.0 |

| Ni | 70.0 min |

| Cu | 0.50 max |

| Co | 1.0 max |

| Ti | 2.25-2.75 max |

| Al | 0.40- 1.0 |

| Fe | 5.0- 9.0 |

| NB | 0.70- 1.20 |