-

Stainless Steel Sheet Plate

-

Stainless Steel Coil Strip

-

Stainless Steel Tube Pipe

-

Stainless Steel Bar Rod

-

Galvanized Steel Sheet

-

Galvanized Steel Pipe

-

Carbon Steel Coil

-

Carbon Steel Pipe

-

Carbon Steel Bar

-

Gi Corrugated Sheet

-

Wear Resistant Steel Plates

-

Carbon Steel Sheet

-

Galvanized Steel Coil

-

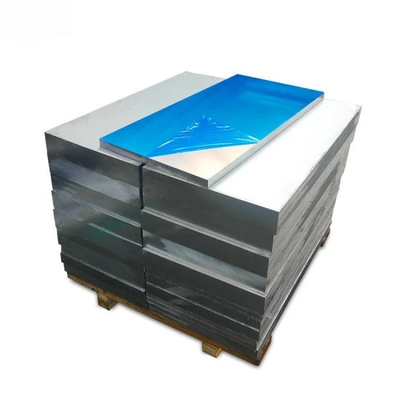

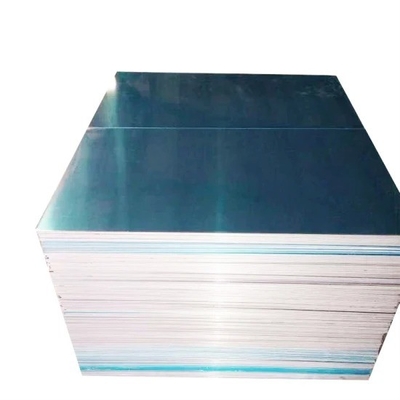

Aluminium Sheet Plate

-

Copper Sheet Plate

-

Nickel Alloy Steel

-

316 SS Plate

-

304 Stainless Steel Tubing

-

ReaxionsI was going to use it for a block-off plate on an engine, but it ended up using 8mm aluminum, instead, as it's easier to cut, shape, and drill, but this is quality SS, and I'll definitely use it on another project.

ReaxionsI was going to use it for a block-off plate on an engine, but it ended up using 8mm aluminum, instead, as it's easier to cut, shape, and drill, but this is quality SS, and I'll definitely use it on another project. -

T. F.It is what it is. What more can really be said? I've ordered two of these. Both arrived packaged very well. No warps, bends or scratches. Recommended!

T. F.It is what it is. What more can really be said? I've ordered two of these. Both arrived packaged very well. No warps, bends or scratches. Recommended! -

DMannThe purchasing process was easy and efficient, and I appreciated the timely delivery of my order. Overall, a great experience.

DMannThe purchasing process was easy and efficient, and I appreciated the timely delivery of my order. Overall, a great experience.

5754 6083 T6 3003 O Temper Aluminium Sheet Plate 0.3mm 0.5 Mm 1/16" 1/4" 1/8"

| Place of Origin | China |

|---|---|

| Brand Name | Aluminium |

| Certification | ISO, AISI, ASTM, GB, EN, DIN, JIS |

| Model Number | Series 1-8 |

| Minimum Order Quantity | 1 Ton |

| Price | Contact Us |

| Packaging Details | Waterproof Paper, Steel Strip Packed and other Standard Export Seaworthy Package, or customized package |

| Delivery Time | Within 7-10 Working Days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 5000 Ton/Tons per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Surface Treatment | Mill Finish | Surface Technical | Corrugated/Perforated/Embossed/Water Ripple |

|---|---|---|---|

| Applications | Ships, Refrigerators, Molds, Aerospace Equipment | Technical | Hot Rolled/Cold Rolled |

| Specification | 4X8FT/5X10FT/Customize | Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

| High Light | 3003 o temper aluminum sheet Plate,aluminum sheet 0.3mm,aluminum sheet 0.5 mm |

||

China Supplier 5754 6083 T6 Alloy Custom Temper Aluminum/Aluminium Sheet for Building Materials

The 7-series aluminum alloy belongs to al-zn-mg-cu super hard aluminum alloy, which has been applied in the aircraft manufacturing industry since the late 1940s and is still widely used in the aviation industry.

Its characteristic is that after solid solution treatment and plastic, heat treatment reinforcement effect is very good, under 150 ºC has high strength, and has very good strength at low temperature;

Poor welding performance;

Prone to stress corrosion cracking;

It needs to be coated with aluminum or other protective treatment.

Double - stage aging can improve the ability of the alloy to resist stress corrosion cracking.

Aluminum sheets

Main products include 1-7 series aluminum plate/strip/coil/foil. We also produce mirror aluminum sheet, aluminum checkered plate,

tread plate, embossed aluminum plate,etc

a.Light weight

b.Low cost

c.Easier and convenient to install

d.Environmental friendly and energy saving

e.Anti-dirt and self-cleaning

f.Corrosion resistant and moisture proof

g.Weathering resistance stronger than stone material and valid time longer

h.Excellent ductility, can be made into various shapes

Aluminum coil/sheet is widely used in electronics, packaging, construction, machinery and other fields.It is divided into pure aluminium plate, alloy aluminium plate, thin aluminium plate, medium and thick aluminium plate, pattern aluminium plate. At present, the aluminum sheet grade that our company can supply:1050, 1060, 1070, 1100, 2024,3003, 3004, 3005, 3102, 3105,5005, 5052, 5083, 5086, 5182, 5754, 5154, 5454,6061, 6063, 6082,etc

![]()

![]()

Width: 20-2200mm

Length: Under 6000mm normally or customized

Weight: 0.5-7.0 tons per pallet or customized

Temper: various Temper (HO-H321)

Surface treatment: mill finished and silvery aluminum plain color

Painting type: PVDF (PPG) and PE(polyester)

Color Coating thickness: Topside of coil :25um (PVDF), 16-25um (PE) Backside of coil:8-10um(PE)

Color code: Solid color as per RAL Code, wood color, marble color, or customized

Performance

1) Long life, lower cost, but has high cost for recovery ;

2) High plasticity, corrosion resistance, electrical conductivity and thermal conductivity, acceptable for contact welding, gas welding;

3) Xinyu Non-ferrous Metal Ltd has a strict control of product and processing, composition to ensure the product performance reached the international advanced level;

The performance of PE color coated coil

1) Thickness≤0.5mm

2) The performance of PVDF color coated coil

![]()

![]()

![]()

![]()

Q1. Where is your factory ?

A1: Our company's processing center is located in Jiangsu, Wuxi, China.

Which is well equipped with kinds of machines, such as laser cutting machine,mirror polishing machine and so on.

We can provide a wide range of personalized services according to the customers' needs.

Q2. What are your company's main products ?

A2: Our main products are stainless steel plate/sheet, coil, round/square pipe, bar, channel, etc.

Q3. How do you control quality ?

A3: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q4. What are the advantages of your company ?

A4: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q5. How many coutries you already exported ?

A5: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt,Turkey, Jordan, India, etc.

Q6. Can you provide sample ?

A6: Small samples in store and can provide the samples for free.

Customized samples will take about 5-7days.